VG-21

Maintenance Item # 17 ††††††††††††††††††††††††††††††††††††††††

9 May, 1995

FUEL

SYSTEM:

FUEL TANKS:

There is one 17.5 Gallon welded/riveted aluminum tank in each outboard wing for

as you know, a total of 35 gallons. These tanks and all their parts except the

filler neck were manufactured by Varga. The most

A leaking

sender is usually easy to fix by either tightening the flange screws or

replacing the flange gasket which is available at most aircraft supply houses.

If one of

your Curtiss CCA-1550 quick drain valves stop working, most likely you will find it plugged with

sloshing

Loose

rivets and cracked welds are a bigger problem. First make sure that red or blue

fuel residue is not just from a leaky scupper drain (see SCUPPER below). If

not, youíll have to disconnect all attaching hardware, remove the outer wing,

drill out rivets to remove the center wing rib, loosen the tank support straps

and slide out the tank.

The rivets

are special jacketed types (P/N 44401ADJ4-5-4) installed before the end was

welded on. If you have a leaking rivet you have two options that I know of. (1 ) You can carefully grind off the weld that holds on the

end of the tank, drill out the offending rivet and replace it (lf you can find

a jacketed rivet to replace it with. We also sealed each rivet with #242 Locktite on later airplanes), clean out the sloshing

If you have

a cracked weld, clean out the sloshing

FUEL

VALVES: As you know, there is one shut-off valve for each tank. This Imperial

Eastman brass plug valve is still available from many sources including

Aircraft Spruce and Wag-Aero. Lee

GASCOLATOR:

Edo-Aire made the G199-105 gascolator

that was used on the Varga. It may still be available

from the manufacturer who bought the production rights from Edo-Aire, but if you need repair or replacement parts, I donít

know who that is. There are other (much cheaper) gascolators

available that will work (l have one on my airplane), but none have the same attachment

or are certified on the Varga.

ELECTRIC

FUEL PUMP: This is a Facet #476087 fuel pump. I donít know if this part number

is readily available but several aircraft supply houses sell similar Facet fuel

pumps and they may be able to get one for you. Iím not sure if another Facet

part number will work because, on the Varga, the

electric fuel pump is in parallel with the mechanical engine driven pump, not

in series, and there may be something different about this fuel pump that is

important.

FUEL VENTS:

Fuel vents are lines 1/4 aluminum tubing with 1/4 ID flexible hose at each

joint. As Lee

FUEL LINES:

All of the fuel line is 3/8Ē aluminum tube with standard 37 degree AN fittings and standard aircraft flexible fuel hose.

CAUTION; Replace your flexible fuel hose within 10 years or 1000 hours,

whichever

FUEL

CAP/FILLER NECK: The fuel cap is a standard unvented

fuel cap similar to those available from most Supply houses. The only problem

Iíve ever had with one of these was a bad gasket causing the cap to be loose.

The filler neck is also similar to those sold in supply houses.

SCUPPER:

The scupper is the depressed area around the recessed filler neck on Vargas. It

is there to contain and drain away spilled fuel. If the rubber hose that

couples the scupper outlet to the 114í drain line is old and cracked, it may

leak fuel onto the tank and make you think you might have a tank leak. Check

this rubber hose first before you pull out the fuel tank.

FUEL GAUGE

SYSTEM: The fuel gauge system has apparently been a major source of

All

airplanes left the factory with a tested and functional fuel gauge system.

Every fuel gauge was inspected with a test device provided to us by Rochester

Gauges. The fuel gauges were tested at Full, 1/2 and Empty with precision

resistors and were considered to be acceptable if indicating within a tolerance

of one needle width, except at Empty, which had to indicate a maximum of Empty.

All fuel level senders were measured with a regularly calibrated precision

ohmmeter at Full and Empty positions and had to read a maximum of 0 ohms at

Empty (down) and 15 ohms + or - 1/2 ohm at Full (up). After the airplane was

assembled but before fuel was installed, the fuel gauges were read to insure

that they indicated empty. The gauges were read again when the aircraft was

filled with fuel. If any discrepancies were noted, the system was adjusted or

repaired before the airplane was delivered to a customer.

During the

certification of the Model 2180, we had to recertify the fuel system. This

included fuel tank capacity, acceptable fuel flow for the larger engine, the

amount of unusable fuel and the accuracy of the fuel gauge system. There were a

few interesting things that we discovered during this testing. One was that the

forward fuel outlet and line on fuel tank was unnecessary and perhaps

undesirable. In a steep glide angle with very low fuel, the aft fuel port would

uncover and draw air. We removed the forward fuel line on the Model 2180 but

went out of business before we made the change to the Model 2150. Another item

of interest was the fuel quantity test. When a tank was filled with fuel by

quantity, less than 17 gallons were installed, but when weighed and its weight

adjusted for fuel temperature (it was a hot spring day in

One thing

of concern to the FAA was that when the gauges finally said empty, fuel was

exhausted within only minutes. They thought (and we agreed) that the pilot

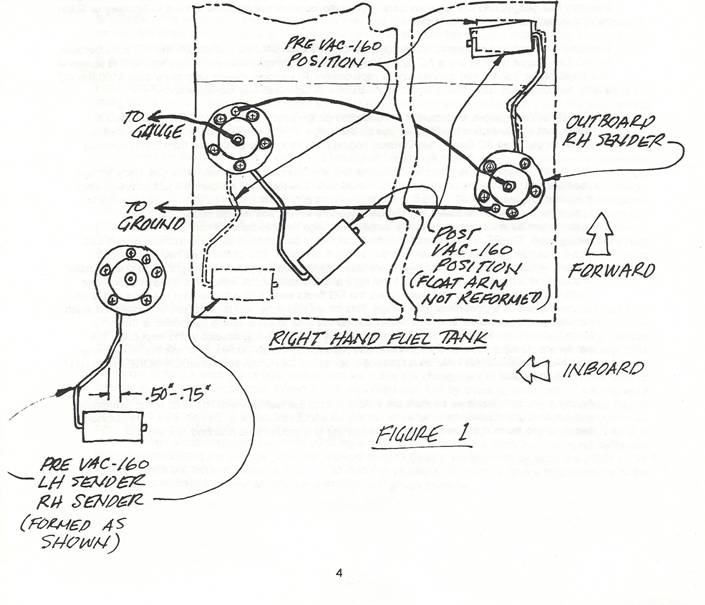

should have more time than that. On fuel systems manufactured for Varga SIN VAC16O-80 and later, two changes were made to

increase the amount of fuel left when the gauges read empty. The first was to

shorten the arm on the fuel level sender to give it less travel and more

clearance for the float at the top and bottom of its travel. In other words,

the sender float bottoms out before it gets to the bottom of the tank. The

second thing we did was rotate the tank fuel level sender mounting flange

inboard(away from each end) so that we no longer needed right hand and left

hand sending units. The effect of these changes was to reduce the accuracy of

the fuel gauge system at Empty, but give an Empty indication well before the

tanks were dry.

Early

Vargas had the same fuel gauge system that was installed on the Shinn,

including some fuel system parts built by Shinn or its subcontractors. I donít

remember when we started to run out of Shinn engine clusters (fuel gauges) and

senders, but I believe Rochester Gauges (RG) was the only vendor that was

willing or able to make replacement parts for us. Although its been said that

there were no problems with Morriseys or Shinnís, it

may be interesting to note that one reason we were running out of original

inventory fuel gauges and fuel level senders is because we were selling some of

them to Morrisey or Shinn owners as replacement or

repair parts.

This

continued to be a problem for Morrisey/Shinn owners

even after we switched to the RG parts because the RG fuel gauges wont fit in

the AC Spark Plug Division (AC) engine clusters, it was hard to find someone

who could repair the AC fuel gauges and a replacement RG engine cluster cost

more than $100 (the AC cluster only cost Shinn about $17), which some owners

thought was way too expensive.

GAUGES:

Fuel gauges are a part of a RG engine gauge cluster which is similar to those

used in Beechcraft airplanes and modified for use on

the Varga. They are really just 0-14 VDC voltmeters.

Early Vargas used AC Spark Plug Division engine clusters that were inherited

from Shinn inventory.

SENDERS:

The RG and

SW units are electrically identical but have some mechanical differences. The

RG senders are aluminum and the SW senders are steel. One problem we had with

the RG senders is that the floats and float arms are also different. Both types

were bought as one part number and the float arms were bent to make them right

and left hand parts. Although the RC senders were made within the tolerances

that were given, the RG floats were a little thicker and the arms had to be

adjusted to within a closer tolerance range. This meant that if the fuel tank

warped or canned too much from the welding process, the floats would sometimes

stick to the sloshing

As

designed, both fuel level senders are insulated from the fuel tank with RG #722

Nylon Grommets and a rubber gasket and are wired in series to give a total

resistance of 0 to 30 ohms. The outboard sender is grounded at its flange with

a wire running to a ground stud attached to a wing rib.

Another

problem reported by Varga owners as a NO MORE THAN

HALF FULL INDICATION (or always empty, if the wires are crossed) is caused by a

grounded inboard sending unit. The screw attaching the ground lead to the

inboard sender is much shorter than the flange attaching screws so that it

wonít touch the fuel tank when tightened all the way. If a longer screw is

accidentally installed, it will go through the gasket, touch the tank and

ground out that sending unit so that it is the only one being read (the gauge

sees 0 to 7 volts instead of 0 to14 volts).

An ALWAYS

EMPTY indication is probably a bad gauge, shorted wire to the sending units, a

shorted inboard sending unit or both sender floats stuck to the bottom of the

tank.

An ALWAYS

FULL indication can be caused by a break (open) in the electrical system (wire,

sender or gauge) or, more unlikely, by both sender floats being stuck to the

top of the tank.

Another

problem is that the senders can just wear out and be faulty by being internally

grounded shorted, giving a less than full range reading or internally open,

giving an always full reading.