NewsLetters

31 December 1999

VG-21 SQUADRON

MORRISEY/SHINN/VARGANEWSLETTER

ISSUE # 41

NEWS:

Bob Marshall now has a supply of muffler hanger springs similar to those used on a Varga (not PMA'd) and will sell a set of 4 for $30. If you need these springs, his phone number is (716) 243-3393 or you may find Bob at 23 Esternay Lane in Pittsford, NY 14534. You may also contact him by e-mail at romarsca@localnet.com.

I'd like to give a welcome to new members Bonnie Harvey of Tylertown, MS, Scott Putnam of Boise, ID, Jeff Johnson of Naples, FL, Dean Owen of Morehead, KY, Dave Casey of Rancho Santa Fe, CA, Ed Maybury of Port Royal, SC, Les Lowman of Daytona Beach, FL, Jack Shuler of Londonderry, NH and Richard Vickers of Newton Square, PA.

I recently had a phone call from Dave Johnson of Ludington, MI who said he was considering the purchase of a Varga. One of his big concerns was the availability of airframe parts. I had to be honest with him and tell him that used parts are getting harder and harder to find and owners were often having to make some of the wearing airframe parts like bushings and bearings themselves.

Dave hadn't flown a Varga and, although he has other airplanes for rent, planned to use the Varga as a personal airplane and possibly as a plane that his son could use while learning to fly. I told him that he probably wouldn't find an easier flying airplane which is what I usually tell everyone who asks about a Varga. Good ground handling, good climb rate, light and smooth flight controls, great visibility, hard to make a bad landing, you know, all the things we like about our planes. My problem with describing a Varga is that I don't really have enough experience with other airplanes to make comparisons that might be most meaningful to potential Varga buyers. I can refer them to or send them copies of old magazine articles but that's not the same as hearing from someone who's had the joy and/or pain of living with an airplane for a long time.

I was wondering if maybe you guys and gals could help me out in that respect. If you can find the time, would you write up a little story (testamonial) about your Varga flying and ownership experiences and, if you can, include some comparison's with other airplanes that you have owned or flown? Don't be afraid to include passenger comments if you have them. I'd like to put together a number of these stories as a flyer that I could send to interested pilots when they ask about the Varga. Something like the following from Jack Shular (who compared the Varga to his Ercoupe) would be great!

Dear Max

THANKS for your MOST WELCOMED letter. I write you now in a state of "excitement."

Just got back from my FIRST two hours of flying 8262J. Went up with a buddy of mine who has owned 5 tail-draggers, so with him in the back seat, I felt safe using the rudders for the first time in l5 years. WHAT AN

AIRPLANE!!!! Climbs like a homesick angel!! Makes me fall in love with flying all over again. The plane does not fly like a grand-piano, as did the ercoupe. It is " ahead " of me a bit right now, but my buddy NEVER had to over-ride me on the controls. The Varga wants to fly, not "drop." So I have to learn to make my patterns a little farther out. But, MAN, does it SLIP nicely!!

As usual, there was one big screw-up. I put my preheater in the front air-scoop, thus nicely scorching the paint about 2 inches either side of the right-hand hinge.Nice brown color . I will have to do a paint repair on the cowl- - - But, that is how I learn. I should have pre-heated down below, by the gascolator. Also, the carb-heat cable or the valve stuck/broke . But then it was 7 degrees F today. So that is an expected bug. Fortunately, unless it's humid, you do not need carb-heat on a Lycoming.

If I may, can I ask you ONE favor??? Do you know the "paint number" or color code of the "white" you used in l978 on the cowl??? I think I can repair the cowl by getting a paint store to mix that color of white, having my mechanic spray the small brown area, and then rubbing it out until it blends.

It may be in your manual, but I have been unable to spot it. Again, you helped give the world a very special airplane, and you helped give ME another positive chapter in my book of flight. Twenty five years now, five owned airplanes, and I am as enamored with flight as I was when I began.

Happy New Year, Max

Jack (Doc)

Dr. Jack Shuler

30 Litchfield Road

Londonderry, NH 03053

FLYING THE WEB:

Tom Herr has recently updated his Varga web site, www.iflyherr.com/vg-21.htm. In addition to other changes, he has added all of the Beery newsletters from #1 to #20 and all of Lee's Maintenance Items. If you have access to the internet, you can now get this valuable information any time. I will be scanning newsletters #21 through #40 and the remaining Maintenance Items in sequence and sending them to Tom as soon as I can find the time.

Several of my Varga owner e-mail addresses seem to be out of date. If you have a new "e-dress", please let me know.

EVENTS:

If anyone is going to Oshkosh this year, now is the time to start planning. Let me know if you plan to go and maybe I can try to help Varga owners get together on their way there and/or back.

The Copperstate Fly-In will probably be here in the Phoenix area again next October, although I've heard a rumor that it may not be at Williams Gateway. I'll keep you posted about that one and if you have another event that you want Varga owners to attend, please let me know and I'll list it in the next newsletter.

PLANES & PARTS:

Link to Vendors / Parts / Service / Tools

OIL TEMPERATURE GAUGE: Bill Pruitt of Instrument Tech says that Rochester Guages will make the Varga Oil Temperature gauge if they get a letter of authorization from the Type Certificate holder, Loren Perry. I have yet to write to Loren. I'll let you know what the situation is as soon as I get his OK.

I was recently asked where to find Varga fuel valves. They are a standard Imperial Eastman plug valve that should be available from most industrial supply stores. At Varga, we used to buy them from a company called Air-Draulics [(602) 254-8414] here in Phoenix which sells pneumatic and hydraulic system components but you should be able to buy them locally if you try. They are used on other aircraft and Wag Aero used to sell them. Univair may sell them as well.

VARGAS FOR SALE

I got his e-mail in October so it may be gone but Tim Keith-Lucas says that he is reluctantly selling his Varga

1978 VARGA FOR SALE

This is the best Varga available and is priced below lesser examples.

2863 hours TTAE 957 hours SMOH 345 hours STOH

Sharp Air Force trainer colors Strobes

Reinforced nose gear and engine basket Marker Beacon

Terra miniature nav/com and transponder Headsets included

Garmin thigh-mount moving map 95XL GPS Terra intercom

Parts and service manuals complete records

$41,000 Contact at 931 598-0562 (home) 598-1317 (office).

This airplane is hangared at the Sewanee-Franklin County Airport (UOS). You

are welcome to stop in to see it during airport operating hours.

Vargas are called the "poor man's T-34." They are a two seat tandem

certified aircraft with a Lycoming 0-320 engine. Cruise is better than a

Cherokee 140, and climb is spectacular. Canopy visibility is great, and the

push-rod stick controls are very crisp and quick. Stability is almost that

of a Cherokee. They are a lot of fun to fly, and are reasonable VFR

cross-country aircraft.

Construction of a Varga is part steel tube (aft end of cabin forward) with

aluminum skin and part monocoque. This design facilitates access for

maintenance.

This Varga has an excellent engine (compressions in the 70s, one quart of

oil after 17 hours). The cylinders are Cerichrome.

This Varga was damaged in a back-taxi nose gear collapse at the Winchester

airport in November 1996. The nose gear and the engine basket were rebuilt

greatly overstrength, removing one weak point in the design. At the same

time, the propeller was replaced with a new Sensinich giving better cruise

performance, and the bottom end of the engine was overhauled during the

inspection of the crankshaft.

If I were to continue flying I would keep this airplane. It has been an

excellent personal aircraft, a lot of fun, and economical to own.

Timothy Keith-Lucas, Ph.D.

Professor of Psychology

The University of the South

735 University Avenue

Sewanee, TN 37383

931 598-1317

----------------------------------------------------------------------------------------------------------------------------------------------

Trade-A-Plane:

1977 VARGA KACHINA, TA 1400, 400+ factory

new engine. 170B w/VOR, KT76A w/Mode C, Loran, NDH,

228,463-9080, www.airshow.net/parkerrhett.

1978 VARGA 2150A, 1807TT, NDH, KX-170B, KT-

76A/ encoder. New intercom, fuel selectors, shimmy

dampener, tires, battery, seat covers, belts/ harness,

vacuum pump, strobe power supply. Added military

decals, Hobbs meter, G-meter, overhead canopy glass,

oil filter kit. $34,000. 760,438-7680.tf

----------------------------------------------------------------------------------------------------------------------------------------------

MEMBERS & OWNERS:

VG-21 Membership: A $20 annual donation will cover all the printing and mailing costs for at least four issues a year and will help pay for return phone calls, letters and postage when you have questions or comments that require a quick or personal response. Beery VG-21 Newsletters: $10 covers most of the printing and mailing costs for all issues. Old Bishop VG-21 Newsletters: $1.00 per issue (includes postage).

For those of you who don't know, I am the former Varga Aircraft Corporation engineering manager (1975-1982) and may be able to help you with a problem. I can be reached at:

Max Bishop

2062 West Gila

Chandler, Arizona 85224

(602)786-3578 (evenings)

(602)891-6152 (days)

e-mail: maxbishop@gowebway.com

You may also be able to find me at hanger A9 or hanger RR2 at Falcon Field in Mesa.

DESIGN:

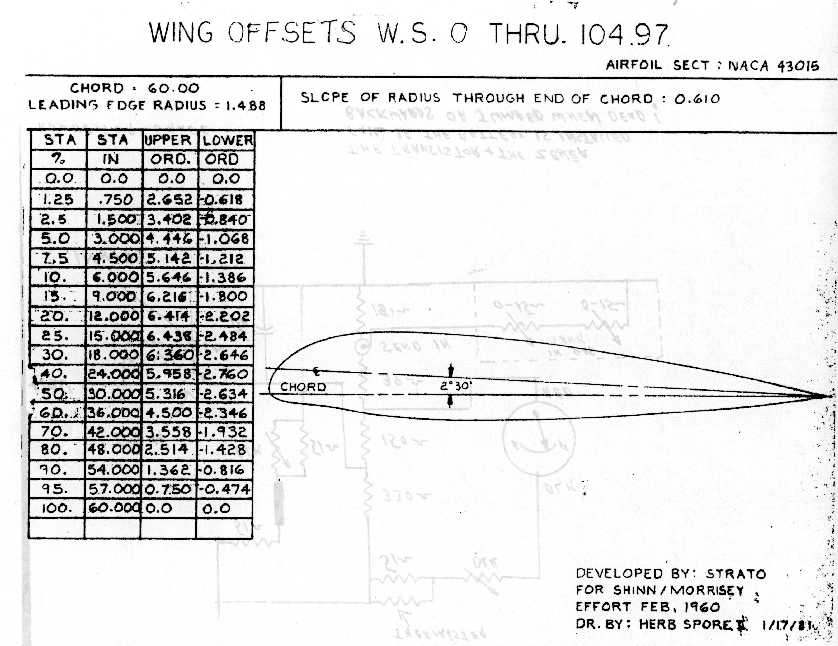

I don't get many questions about it any more but when I was at Varga, I got lots of inquiries about the choice of the airfoil used on the Varga. Most of the those who were curious had noticed the concave skin area under the leading edge (undercamber) and assumed that it meant that the wing had some high lift characteristics. They were right of course but it wasn't until I got involved in trying to show that, during flight tests for the model 2180, the airplane was characteristically incapable of spinning that I found out a lot more about this particular airfoil and it's other characteristics.

As many of you know, the wing of the Varga is built in three parts consisting or the center wing (we called it the stub wing) and the left and right outer wings. The center wing has a 60 inch chord, about a 7 foot span, attaches to the fuselage truss and contains the main landing gear. The outer wings attach to the stub wing with splice plates and the joint at the attachment is covered by a removable fairing. Each outer wing is made in 2 sections with the inboard 5+ foot span having a constant 60 inch chord and the outer 6+ foot span tapering in both chord and thickness. The right and left outer wings are the same (except for being right and left of course) except the right wing has the pitot and stall warning parts installed. The wings also have no washout (twist).

During the development of the airplane, Bill Morrisey decided to use the NACA 43015 airfoil section. The 43015 is one of a series of 5 digit airfoils. Other light airplane makers have used the 5 digit 23015 airfoil because it has a good balance between lift, drag and stall characteristics. Relatively good lift, relatively low drag and relatively gentle stall. I think Van's RV-3, RV-4 and RV-6 series of experimental airplanes use a 23012 airfoil and are reported to have very good flying qualities with this wing.

I'll explain a little about the choice of the 43015 airfoil but, to keep this discussion simple, I'll only talk about the meaning of the first and last two digits of the airfoil.

The first digit is a multiplier that tells us what the design lift coefficient should be (how much lift should this airfoil have). The bigger the number, the greater the lift. The last two digits are a multiplier that tells us how thick the airfoil should be relative to it's length. For example, a 03015 airfoil with a 60" chord would be perfectly symmetrical about a line from it's leading edge to it's trailing edge (chord line), have a zero lift coefficient (no lift when flown parallel to it's chord line) and be 9 inches thick (15% of 60 inches) at it's thickest part. An interesting thing about this particular airfoil series is that, as the first digit gets bigger, forward of about the 15% chord line, the more the nose of the airfoil droops. In other words, from about 9" back from the nose to the trailing edge, the top and bottom of the airfoil have exacly the same curve.

I don't know if it was the intention but, when designing the production Morrisey, using this type of airfoil would have made it easy for Bill and his design guys to easily change the flight characteristics of the Morrisey by just changing the leading edge of the wing. This near symmetry also made the wing somewhat easier to manufacture.

One reason Bill might have wanted this option is because, although the 43015 was reported to have very high lift, it's lift curve also showed it to have very sharp (and possibly unacceptable) stall characteristics. From what I remember and what I've read, it was decided that if the elevator travel and CG range were limited, the stall characteristics should be moderate enough to be acceptable. As time has shown, with the choice of this airfoil, along with the choice of wing planform (wing shape when viewed from the top), Bill got exactly what he wanted.

During the flight test of the model 2180, with the airplane loaded almost half an inch aft of the aft CG limit and rigged with 20 degrees of "up" elevator instead of the normal 16 degrees, full flaps and full power, the FAA test pilot was able to experience the potential sharp stall characteristics of this airfoil and subsequently entered an unrecoverable spin (he recovered with a spin chute). After rerigging the airplane with the correct elevator travel, spin tests were resumed and concluded with normal spin recoveries within 3/4 to 1 turn. There were also reports from a Model 2180 taildragger owner that, when loaded aft of the CG limit (I don't know how far aft), although there was no tendency to spin, he would sometimes experience what he described as a "whip stall".

An FAA test pilot told me that if the tendency to enter a spin could be stopped with the rudder, the stall characteristics of that airplane would probably be acceptable to the FAA. Most Vargas show little tendency to fall off to the left or right during a stall and, if they do, the ailerons are usually still effective enough to control any roll tendencies. Some Varga owners have reported spinning the Varga but, based on what I've seen in flight tests, I suspect their spin was more like a stalled spiral. I'd be interested to know if any of you have experienced anything different.

If the Varga is rigged properly and within it's CG limits, I don't think you will ever get into trouble unless you screw up too close to the ground. Pilot induced stall/spin accidents in a Varga appear to be very rare.

MAINTENANCE:

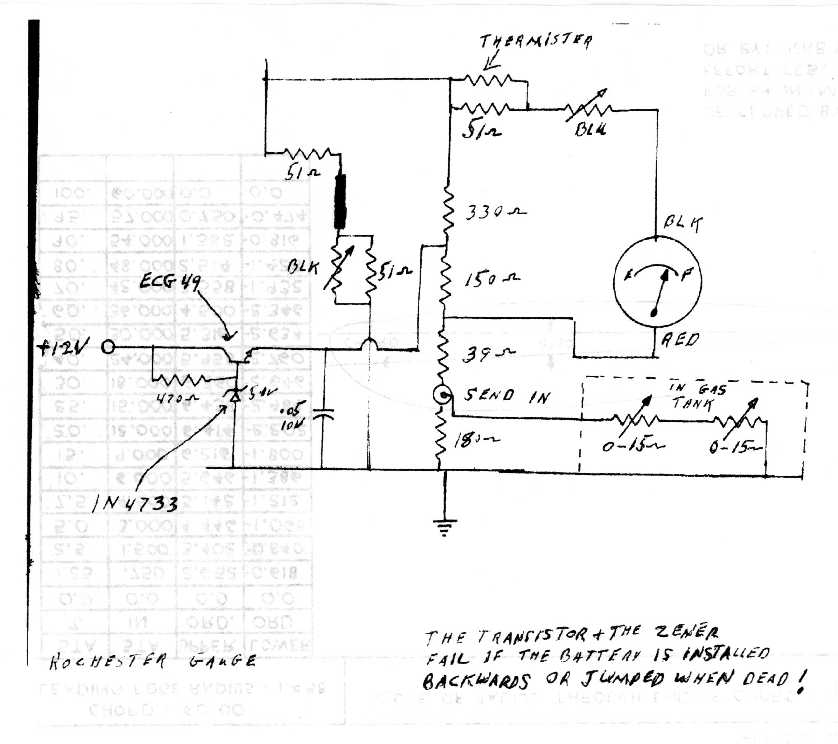

I have enclosed a schematic of the Varga fuel gauge that was sent to me by Bob Marshall. He was able to fix his gauges by replacing the indicated transistor and zener diode. I don't know if it uses the same components but, Bob says the same repair works for the oil temperature gauge.

I was hoping to be done by now but was too optimistic and probably won't be done with the reassembly of N2103Z until the middle of this year. The reconstruction of this airplane has forced me to make a lot of tools in order to make new parts. There were enough borrowable tools around Falcon Field to make the necessary new skins and bulkhead repair parts so I got the aft fuselage back together over a month ago. Over the Christmas break from my work at Boeing we got the left wing reskinned and all the remaining ribs we need for the right wing and next airplane are formed and awaiting heat treat.

I now have templates and form dies for most of the outboard wing ribs and we have made forms for the fiberglass wing tip molds. With some ideas from Kitplanes magazine, we built a press brake from wood to form the leading edge skins and it worked better than I had expected. We were able to form both inboard and outboad leading edge skins for both airplanes. We still need to pour the wing tip molds from tooling plaster and get them prepped to make parts but we won't have time for that until after we get the right wing back together. We made a large wood assembly fixture and are well on our way to completing the reassembly of the right wing.

I have ordered a new canopy bubble for N2103Z ($1,000) and expect to get it in late January.

My next priority is to make weld fixtures for both the upper and lower landing gear. The second airplane will be tricycle gear so I will need to make fixtures for both tri-gear and taildragger upper struts. The lower struts are the same for both tri-gear and tailwheel airplanes. I was easily able to get all the landing gear steel aircraft tubing and sheet metal that I needed except for the vertical tube on the lower strut. It is supposed to be 1 7/8" x .083 wall 4130 tubing but I could only get 1 7/8" x .095 wall. I am having trouble getting the inside diameter (I.D.) bored to the correct dimension (1.709") here in Phoenix and, if I have to, I could grind the spring and other parts down to the smaller I.D. on my plane because it's experimental but that might be a problem for certified airplanes.

We will eventually need them but probably won't make stub wing parts and assembly tools for the second airplane (now assigned N6220X) until late this year or early next year.

I don't have time right now but as soon as I can after I get N2103Z back in the air, I'll try to figure out a way to make airframe parts for others who need them.

Shinn Ag-Master photo furnished by Doc Adams

PERSONAL NOTES: A personal history of Varga Aircraft (continued).

Continuing the story from issue # 39:

I left off the last time with Mr. Varga taking on a consultant and borrowing some money to increase production. As I mentioned before, at least up to this point, we always had a backlog of more than 20 airplane orders. We were able to borrow construction money against each order and pay back the loan upon delivery of the aircraft. This worked OK but didn't leave us any money to grow to a profitable production rate.

The consultant was convinced and convinced Mr. Varga that we were making a small profit on each airplane and, with just a minimal amount of extra money, we could increase the profit to some self-sustaining point. There was an attempt to tell the consultant that the only reason we could possibly be making a profit at the 2-3 a month production rate was because some of us were working 60+ hour work weeks. There wasn't enough free time in a day for those of us putting in that extra free labor to make enough parts to double or triple the production rate. And, if paid labor was used to fill in for all the free time, the profit would go away. The complaint fell on deaf ears and we forged ahead anyway.

By using the extra money to buy more raw material and hire more production people, we did increase the production rate of 2 aircraft a month in April of 1980 to almost 5 aircraft a month by October of that year. In addition, the consultant convinced us that we should pursue Model 2180 certification and we began the conversion of a borrowed airplane (N1901A) for that project. This consumed additional resources that were already stretched too thin and added significantly to the engineering and production burden. Unfortunately, although our production rate did double, our sales rate stayed at 2-3 a month. We ate up our backlog without an increase in sales and, towards the end of the year, had to lay off our extra employees and cut back to our original production rate. We were back where we started except that Mr. Varga now had an additional debt to service due to the cost of the attempted expansion. We also had an added production problem caused by the premature advertising of the Model 2180. Although our backlog started to return, people who already had orders in for 2150's wanted to switch to 2180's and all new orders were for Model 2180's. The time it took to ramp up production parts for the new model and certification delays almost halted production and, by the end of 1980, things were real tight. We were in dire need of more money to keep going and, personally, after about five years of long hours at low pay, I was beginning to run out of steam.

Shinn Ag-Master photo furnished by Doc Adams

FUEL GAUGE SCHEMATIC: