Varga / Shinn VG-21

Squadron

MAINTENANCE ITEM

#4

*** FUEL VENT

SYSTEM ***

By Lee Beery

For some reason, the Varga fuel vent system is rather involved and

does not work very well. I'm sure that

every Varga owner has left large puddles of fuel on the ground from time to

time after refueling. Due to the design

of the vent system, the only way to prevent this from happening is to never

fill the tank completely. If the

fuel level is kept approximately 1/2 inch below the neck, chances are you will

not spill any fuel. However, if you fill

the tank right up into the neck, chances are good that a siphon will start and

several gallons of fuel will be spilled.

At the Arlington,

WA EAA convention last summer, I

discovered that the Glasair aircraft had a similar problem and was corrected by

routing the vent line outboard to the wing tip.

I propose to go to the FAA with a similar request this spring. I need a

Varga owner to join forces with me in the endeavor. I plan to work with the Oakland FISDO

office. Who wants to help? Until we get an approval to change the

system, every effort must be made to keep fuel and fuel vapors out of the fuselage.

Inspect the rubber hoses that connect the aluminum tubing vent

lines. With age they become brittle and crack easily. Also, I have found the "T" fitting

that forms the external vent plugged solid by wasp mud daubers. It is hard to believe the engine continued to

run as there was so much vacuum created by the fuel pump that we could not

remove the fuel caps for several minutes.

I suggest you remove the rubber hose connection from the "T"

fitting and run a drill through the vertical portion of the tee to verify it is

not obstructed in any way.

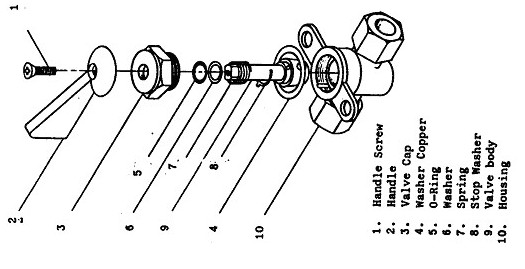

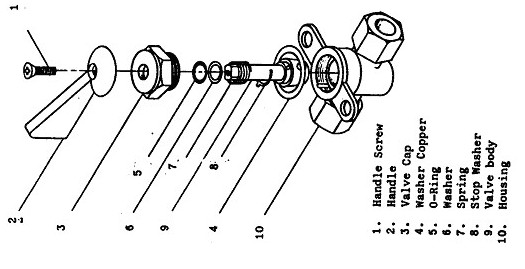

*** FUEL SHUT-OFF VALVES

***

By Lee Beery

If you use these valves on a regular basis, chances are they

operate fine. I have checked the

operation of these valves on several aircraft and have found them nearly

impossible to move. This is a very

simple job but does require a special lubricant. The only product to be used on

these valves is "Sealube" by Fleet Supplies, Inc., Cleveland, Ohio. All you need to do is to remove the wing

fairing (do one valve at a time) and clamp the fuel hose with vise grips to

keep fuel from flowing, remove fuel valve handle and valve cap. Lift off O-ring, washer, and spring as a

group. Remove stop washers and then pull out valve body. Clean/polish valve boar and valve body with crocus

cloth, coat with "Sealube" and reassemble valve in reverse order.